Wisdom and Creativity, Sharing Responsibilities and Benefits

NFK Air Cooler

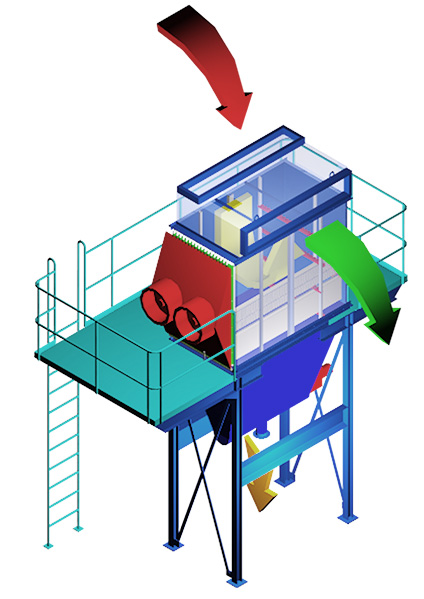

NEOTECHNIK surface air cooler is designed to cool the hot exhaust gas (about 550℃) generated by melting furnaces such as cupolas, converters, vertical furnaces, etc. Hot exhaust gas enters the cooler from the top. The axial flow fan draws air from the atmosphere and exchanges heat with the hot exhaust gas on the outer surface of the horizontally installed metal cooling bag.

In addition to lowering the temperature, the surface cooler can also preliminarily separate coarse dust particles in the hot exhaust gas. The separated dust is discharged by the screw conveyor and the double pendulum shutter. The cooler can be equipped with a full-automatic cleaning device to continuously remove the dust that may be generated as needed.

Product Structure

The filter housing is processed by welded reinforced steel plates. The cooling fan is fixed on the openable air introduction cover so as to check the cooling bag and maintain easily.

The cooling element consists of a single galvanized or other surface treated cooling bag. The cooling bag can be conveniently assembled and disassembled from the front by means of the locking handle.

A group of steel chains can be installed on the rotating arm of the automatic cleaning device, if necessary, and the movement of the steel chains can drive dust particles away from the outer surface of the cooling bag.

Product Advantages

- The best gas distribution system

- Stable filtration wind speed

- Very high waste exclusion possibility

- Long operating life of filter materials